AG Cilander is synonymous with top quality according to every standard; this is partly because all the textiles that are put through our finishing process are subjected to regular inspections. This is the only way we can be sure that we meet our customers' expectations. As well as continuous process monitoring, we are especially proud of our in-house testing lab. Here, we are able to assess the strict demands placed on our finished textiles using any of our 400 suitable testing processes, which enables us to guarantee reliable top quality.

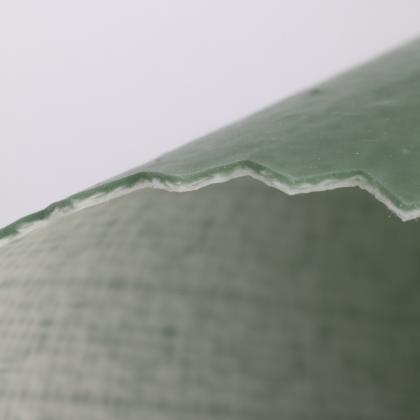

Waterproofness is an essential factor for functional clothing and canvas materials. Impregnated and coated materials should allow very little water to pass through them, if at all. They are subject to the EN 20811 standard. A "water column" can be used to test how waterproof these materials are. It determines the water pressure at which a material begins to allow water to penetrate it. The higher the value, therefore, the better the material will protect against rain.

A spray test can also be used to test light and medium-weight materials. This is used to assess how well the textiles repel water. Square samples of the material are exposed to a specific quantity of artificial rain. After the water has run off the fabric, it is tested using an ISO assessment standard.

The Bundesmann water repellency tester is an item of equipment that we use to determine how much water a fabric will absorb and allow to penetrate it. Over a specified time period, we allow a defined quantity of artificial rain to fall on the textiles. We then calculate how well our fabric repels water and how much water passes through it in accordance with ISO 9865.

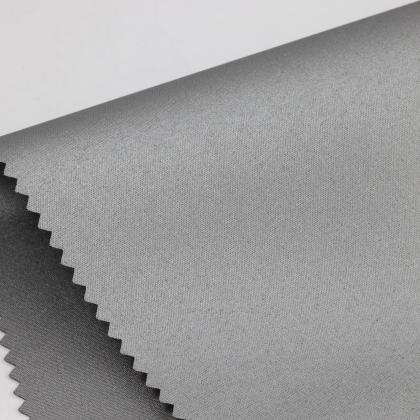

The strength and stretch behaviour of a fabric are often important factors in determining its suitability for its intended function. We use a range of different tests to assess a fabric's tear strength. The tensile test, for instance, involves gripping the material between two clamps and then pulling it until it tears.

Another essential element in testing is the burn test. This examines the fabric's burn behaviour, its flammability and how easily the flames spread. The position of the material (e.g. horizontal for carpets, vertical for curtains) and source of ignition (e.g. cigarette, Bunsen burner, match, etc.) are varied depending on where the textile is to be used. The smoke produced by the fabric and any toxic gases it contains can also be examined during the burn test.

The colour fastness test is a key indicator of how long a dye or print will last and how it could change as a result of external influences. Depending on the area of use, textiles are dyed to be more or less colourfast. For instance, clothing must remain colourfast after being washed, while parasols must retain their colour despite being exposed to light. We can assess colour fastness using a "grey scale". This can reveal changes in the colour depth, tone or purity. Often, all these changes are present simultaneously. In this case, our testing is based on the extent of the visible contrast between a treated sample and an untreated sample.

The air permeability of textiles used in clothing is of particular importance in the functional clothing and technical products sectors (e.g. parachutes). In fabrics, the permeability can significantly affect how the human body is able to regulate moisture and temperature. In the case of parachutes, an air permeability test provides important information about its suitability for use. We measure the flow speed of the air that penetrates a defined area of the fabric at a specified differential pressure in accordance with EN ISO 9237.

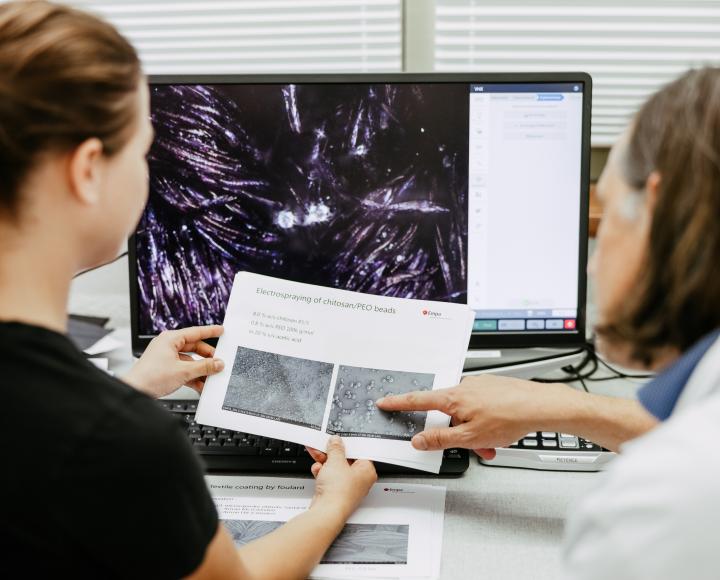

We use a high-resolution digital microscope to examine the fabrics that have undergone our finishing process down to the smallest detail. This enables us to magnify the material up to 2000 times, allowing us to see all the potential reactions that wouldbe invisible to the nakedeye and unidentifiable at the magnification levels offered by simple microscopes.

AG Cilander uses a scrub tester to test how resistant dyes, paints or coatings are to scratches, wear and colour losses. This simulates the wet or dry friction that the fabrics would be exposed to on a day-to-day basis during cleaning or general use.

You are here

Guided by our slogan – we add real, lasting value to textiles – we finish a wide range of materials, including clothing fabrics and technical textiles, to imbue them with additional properties.

Office

Senfa Cilander Switzerland AG

Cilanderstrasse 20

9100 Herisau

SWITZERLAND