up to 360 cm fabric width

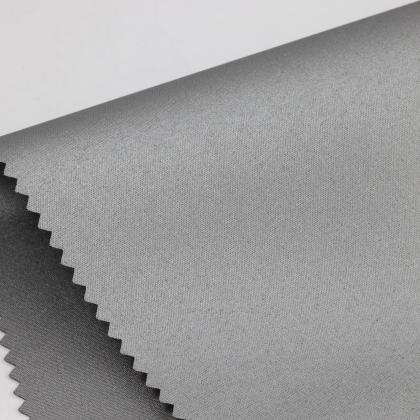

Through the use of state-of-the-art systems, AG Cilander can dye textiles measuring up to 360 cm wide using different dye classes and dyeing processes, depending on the type of fibre or substrate and the intended area of use. In this process, we always focus on delivering the best possible colour accuracy, vibrancy and colour fastness for our customers. All our discontinuous systems are also HT machines. Our dye formulations are created using a colour metric system.

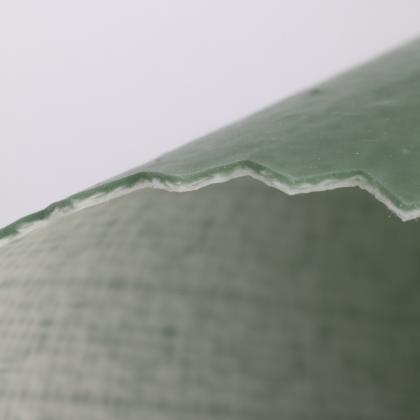

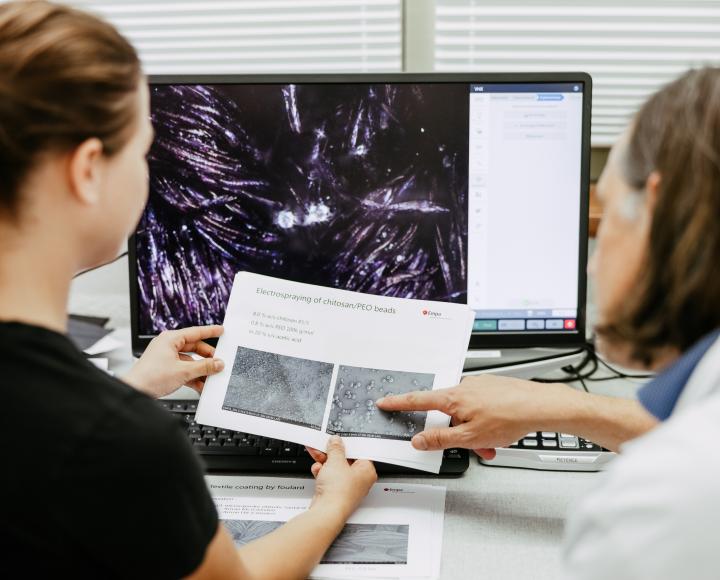

In our continuous dyeing system, we apply dye solutions to the substrate using the foulard process. The material is evenly wetted with the dye liquor across its entire width using hard rubber rollers, which determine the defined liquor absorption during the squeezing process. Next, we fix the dye on the fibres using steam or dry heat. Using dry heat as part of the Thermosol process, we are able to guarantee continuous dye on polyester and polyester mixtures to an excellent quality standard.

The following process is used in our pad dyeing system:

In the cold pad-batch dyeing process – or CPB for short – we apply the dye to the substrate using the foulard method. The fabric is evenly wetted with the dye liquor in the foulard machine. Next, we fix the dye into the fibres by leaving it for a batching time. Lastly, we remove any unfixed dye from the fibres in a washing process in order to achieve excellent colour fastness.

In addition, discontinuous methods are also used:

Our jet dyeing machines are incredibly versatile. They take their name from the jet nozzles they use, into which the dye liquor is pumped. The negative pressure this creates at the nozzle outlet causes the fabric to be sucked into the nozzle. This achieves excellent colouration. The nozzle pressure is adjusted depending on how delicate the fabric being dyed is. Since our jet dyeing machines work using a low longitudinal tension, they are ideally suited for full, voluminous materials with a soft feel. The lack of longitudinal tension can also create a crepe effect.

The fabric beam dyeing machine – or beam for short – includes a horizontal dye container known as the autoclave, into which fabric wound around a perforated beam is inserted. Once the container is closed, the liquor is pressed through the material to be dyed using strong pumps. This closed system is ideally suited for dyeing easily creased or stretched fabrics at high temperatures. The maximum goods width for this process is 350 cm.

Using the jigger dyeing machine, we can handle the entire width of the fabric. Dyeing using this machinery offers benefits and drawbacks. The low liquor ratio and resulting cost-efficiency are, by far, the greatest advantages of this system. However, due to the relatively high longitudinal tension, it is only suitable for unstructured goods, as it may otherwise leave marks. This is why the material is moved backwards and forwards inside a passageway. In addition, the liquor can also be pressed through the fabric as part of this process.

You are here

Guided by our slogan – we add real, lasting value to textiles – we finish a wide range of materials, including clothing fabrics and technical textiles, to imbue them with additional properties.

Office

Senfa Cilander Switzerland AG

Cilanderstrasse 20

9100 Herisau

SWITZERLAND