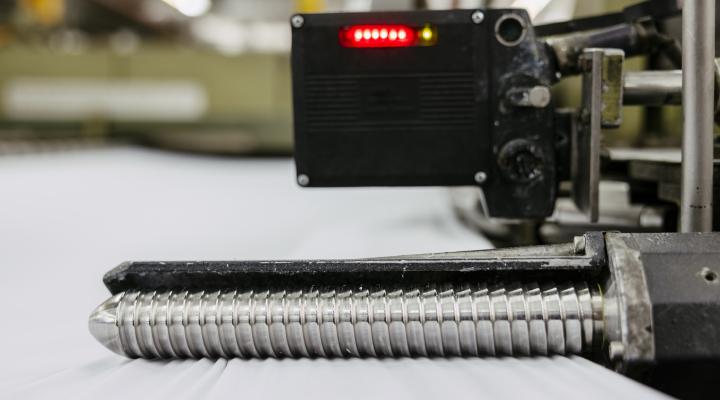

Textile products are subject to many different requirements in terms of how they look, feel and, in particular, function. Our premium finishing processes give fabrics user-friendly properties, such as crease resistance or a water repellent finish. We also provide protective finishes such as the highest standard of flame retardancy.

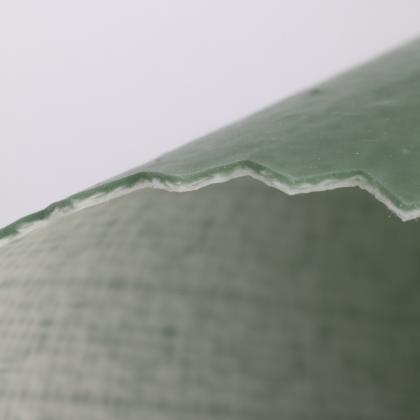

A fabric is considered waterproof if it does not allow any water to penetrate it, regardless of how long it is exposed to humidity or moisture.

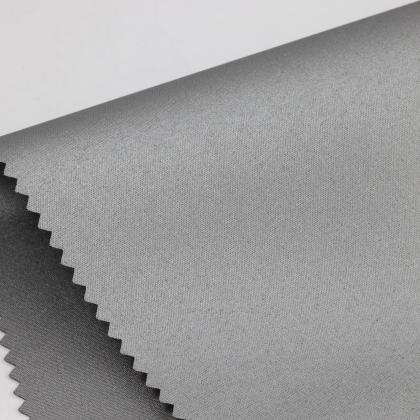

Water-repellent finishing aims to use a hydrophobic finish to create a "pearling" effect. Using fluorocarbon finishing, for instance, we can achieve outstanding, long-lasting hydrophobic effects that are relatively resistant to washing. As the issue of environmental sustainability grows ever more important, so has the process of fluorine-free hydrophobic finishing. Sustainability has always been a priority for us at AG Cilander – and this also includes the development of innovative fluorine-free, water-repellent, protective finishing methods. We develop these in compliance with the rigorous criteria set out by the GOTS standard. Thanks to our state-of-the-art exhaust air purification systems, no harmful waste gases of any kind leave our facilities as a result of our finishing processes.

The Zirpro process is used when finishing wool. Using this method, we perform suitable treatment steps to combine flame resistance with other properties, such as shrink resistance. Another advantage: Since Zirpro-treated wool contains a very low quantity of flame-retardant deposits, the fabric retains its natural qualities, such as moisture absorption and grip.

Permanent flame resistance – i.e. resistance that is not compromised by washing – is a particularly high priority in the protective clothing sector. In this field, we use the latest high-grade finishing technology, which is capable of combining multiple finishes, for instance to guarantee compliance with applicable EN standards. AG Cilander also offers tailor-made solutions for complex challenges, such as combining permanent flame resistance with excellent water- and dirt-repellent finishes.

A PROBAN finish is used to give cotton or textile surfaces with a high cotton content an effective, wash-resistant, fire protection finish and, at the same time, retain their natural properties, such as breathability and feel. Low fogging, which means that no fumes are generated in the event of a fire, e.g. in a car or plane, means that we can comply with the strictest standards set out in the aviation industry.

As a global industry leader, we are continuously developing our range in the top-quality non-iron segment to include more and more innovative functions. These include anti-smell properties (the fabric absorbs bad smells and keeps the wearer feeling fresh all day long) and extra comfort (significantly improves breathability). To prevent the fabric from creasing when wet or dry, we interlink the cellulose chains in a fabric using synthetic resins, which restricts how much they can move around and swell up. In this field, AG Cilander offers a truly unique USP: Wet cross-linking. In this complex, extremely precise process, an elastic bridge is created between the cellulose molecules, enabling the fabric to return to its original form after being washed. The result? Abrasion resistance and tear resistance are maintained for longer, compared to dry cross-linking.

Conventional synthetic resin, which makes fabrics easy to care for, is part and parcel of our standard high-grade finishing service; at AG Cilander, this process uses synthetic resins that are low in formaldehyde. Of course, we are more than happy to use formaldehyde-free finishing processes upon request. This is becoming more and more relevant in terms of protecting the environment and ensuring fabrics are kind to skin. The typical dry cross-linking process is also part of our high-grade finishing range. In this process, dry goods are impregnated with a resin solution and then dried on the tensioning frame. The resin condenses out when acidic compounds, salts of organic bases or heat are added; any residue left over is subsequently washed out.

One of the oldest textile finishes is water resistance – processes for making fabrics resistant to water date back to ancient times. While our ancestors would have used fat, wax or oils, our modern high-grade finishing methods use suitable chemical substances to achieve this aim. They make it more difficult for water to penetrate the material without affecting its breathability. Depending on the type of fabric, we achieve durable water repellency using a range of technologies and processes.

Our years of expertise in a wide range of sectors, including the automotive, public buildings, transport, military, workwear and furnishing industries, among others, means that AG Cilander is an expert, reliable partner when it comes to fire-resistant finishing. From developing customer-specific solutions and creating finishes in our lab, all the way through to strict inspection steps – everything we do is in accordance with the required national standards.

You are here

Guided by our slogan – we add real, lasting value to textiles – we finish a wide range of materials, including clothing fabrics and technical textiles, to imbue them with additional properties.

Office

Senfa Cilander Switzerland AG

Cilanderstrasse 20

9100 Herisau

SWITZERLAND